Gypsum Lab Services

Gypsum Factory Support - Process and Cost OptimizationUsing a combination of lab measurements and process results we optimize gypsum factory performance and costs to the industry best practice. Plant Data AnalysisInnogyps will review and make recommendations for all forms of big data: process data, quality results, fire test results. Often more data is collected than can be reasonably reviewed and helping to focus on the appropriate measurements that matter. Plant TrialsInnogyps will help plan, implement and attend a gypsum board plant trial for any product including lightweight gypsum board, fire test trials, implementing glass mat products or new processes like rollercoating. Activities may include trial setup and experimental advice, data collection and reporting. Independent BenchmarkingInnogyps measures gypsum, stucco and gypsum board from all over the world. A confidential assessment of your products compared to industry leading competitors will clearly define your improvement goals. Plant Improvement Value AssessmentsInnogyps uses a mass and energy balance cost model calculation of the gypsum board plant inputs and outputs that estimate the efficiency benefits of planned changes or upgrades. Stucco quality improvements including stucco cooling or post calcination conditioning, new formulation additives and line speed upgrades are ideal candidates for this assessment. Troubleshooting SupportProcess upsets and scrap are often due to a variety of factors that can be difficult to diagnose. Innogyps will review background data and measure examples to enable an appropriate course of action backed by data. |

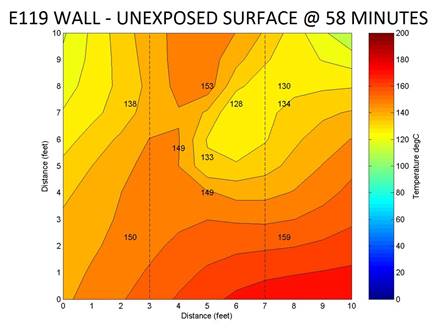

Nail Pull Performance  Fire Test Data Visualization |