Gypsum Lab Services

Gypsum Board Research, Formulation and TestingDo you have a new additive to evaluate for use in gypsum board or a new idea for an improved gypsum board product? Do you need help in evaluating your plasterboard and want to know how your product can be lighter, stronger and more cost effective to produce? Examples of typical gypsum board formulation additives include:

Lab Scale Gypsum Board SamplesTo help our customers to evaluate their products on a reasonable scale without the risk of interrupting a production line, we make lab scale gypsum board samples. The boards can be of any type or formulation from moisture resistant to fire resistant to the latest generation of lightweight gypsum board. The samples can be made using any liner or facer (paper or nonwoven), additives and stucco that are representative of a particular development concept, representative of a target manufacturing plant or can be chosen from popular industry additives to be representative of the most common conditions of operating commercial plants. Gypsum Board TestingUsing lab made board samples or commercial products, we can perform a wide range of physical tests, in particular those from ASTM C473 (Standard Test Methods for Physical Testing of Gypsum Panel Products) or EN 520 (Gypsum plasterboards – Definitions, requirements and test methods). These tests can include nail pull resistance, flexural strength, impact resistance, humidified deflection, shear strength, surface hardness, core hardness etc. We can evaluate fire resistance, thermal conductivity, moisture resistance and mold resistance. We can evaluate wet bond and dry bond to evaluate the performance and process behavior between the liner and the gypsum core. We also offer unique board core structure measurements including microscopy evaluations of gypsum crystal structure, board density distribution, bubble size analysis and nail pull failure mechanism analysis using SEM and/or CT. Examples of research results from such investigations include:

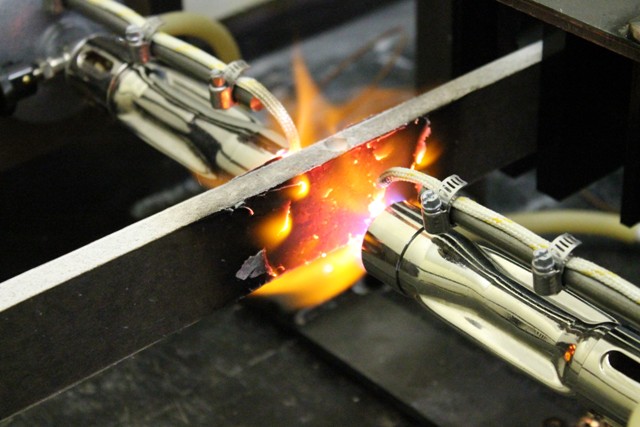

We specialize in reverse-formulation chemical analysis of gypsum products to determine what additives were used in what quantity for competitive analysis and development purposes. This can include glass fibers, fire resistance additives like vermiculite, water resistance additives, mold resistance additives, starches (total use and types used), core strengthening additives such as phosphates, dispersants or foaming agents Lab Scale Gypsum Board Fire TestInnogyps uses an assortment of development tests to help evaluate formulations for suitability in full scale testing including methods described in ASTM C1795. We evaluate sample high temperature shrinkage, cracking, core cohesion, thermal insulation and other system-specific configurations to reduce the risk of failure in costly full-scale system fire tests. Paper and Glass Mat Facer EvaluationInnogyps’ lab can also perform liner testing and measurement for quality control or product development purposes. We have experience in non-paper facers including glass mat products for different applications like sheathing and tilebacker. We also have experience with non-traditional liner materials such as polyester nonwovens. We can perform a variety of paper quality tests that include moisture content, water adsorption analysis (Cobb), porosity analysis (Gurley), thickness and basis weight measurements, machine and cross machine direction tensile strength, wet expansion as a function of time and even slurry penetration and coatings thickness measurements on glass mat gypsum products. Wet bond, dry bond and drying properties can be evaluated using our lab scale gypsum board making process. CAT scan showing the face of a glass mat gypsum board, traveling into the face of the board showing the coated glass mat followed by the gypsum core. Notice the degree of slurry penetration into the mat. |

Flexural Strength Testing  Fire Resistance Testing |