Mark Flumiani and Bob Bruce

Introduced October 2004

The gypsum board industry is very competitive, each company trying to provide better quality products at lower cost. Gypsum companies are responding to these market pressures by reducing board and liner weights. With the increase in fuel costs, efforts have redoubled to reduce energy consumption in drying the board. Reducing board weight and gauging water require the addition of more foam to the mix as well as ensuring that the internal structure of the board is well “engineered” to satisfy the market requirements and meet the required product specifications. The cost savings available for those that are proficient at reducing board weights and energy consumption are significant, amounting to millions of dollars per year for a modern high speed plant.

Efforts to optimize the process and product have been hindered by the ability to quantitatively measure the properties of the core structure in a manner that allows correlation with product performance. A common technique using scanning electron micrographs of polished epoxy filled samples is very expensive and time consuming, and yields only an analysis of a single two dimensional surface.

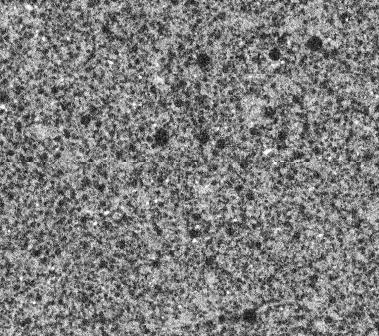

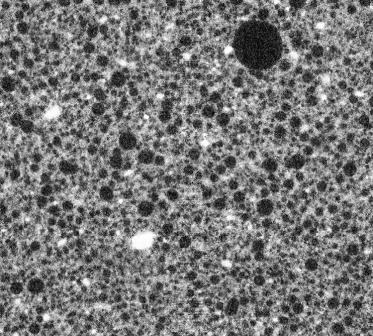

Innogyps Inc. has developed a new technique for the analysis of gypsum board using high resolution CT Scan (Computed Tomography). This technique gives a full three dimensional structure of the core yielding both high resolution images and quantitative measurements of the gypsum core. There is no need to pre-treat the samples in any way, just cut and mount for analysis. The technique is non-destructive so further analysis can be performed on the exact same sample used for CT Scan analysis. The practical resolution is about 20 microns (nominal), making it very straightforward to obtain a bubble size distribution of a typical gypsum board core. A typical analysis will determine the size and position in the sample of about 200,000 bubbles. Higher resolution scans are possible to investigate specific features if desired.

A typical analysis yields the following results:

Qualitative Images

- Images in XY, YZ, or XZ planes at 20 micron intervals between “slices”.

- Movies showing a “fly through” of the sample along any axis (usually XZ or XY)

Quantitative Analysis

- A density profile of the gypsum core along any axis, for example giving the density and thickness for higher density layers adjacent to the liners. This is similar to bone scan measurements for osteoporosis.

- An analysis of the total void content of the board structure, or for any particular volume in space. We typically analyze the regions within 1 mm of each liner, as well as the top and bottom halves of the core excluding these regions (4 regions in total).

- The bubble size distribution for the entire sample, or for any particular volume in space. We typically analyze the 4 regions just described above.

We have analyzed three gypsum board samples that compete in the same market and compared the results described above. In addition to these CT Scan tests we also analyzed the boards for core gypsum content, nail pull resistance and breaking strength (ASTM C473). The intent was to determine if there was any obvious correlation between product performance and core structure. The fact that none of the boards tested passed the nail pull test suggests that some optimization of core structure would be of value.

Although there is work ongoing to further develop the capabilities of this new analysis technique, we have determined that it is mature enough to offer this as a service for those who would like to use it to optimize their products and processes. A report has been written that discusses the basics of how the measurements were performed, along with the results obtained. This report is 18 pages in length with the full results for the three commercial samples each segmented into four regions. The report is accompanied by a QuickTime movie for each sample showing the core structure in the XZ plane.